September 10, 2025

Rethinking Robot Electronics: Building a Unified, Modular Architecture

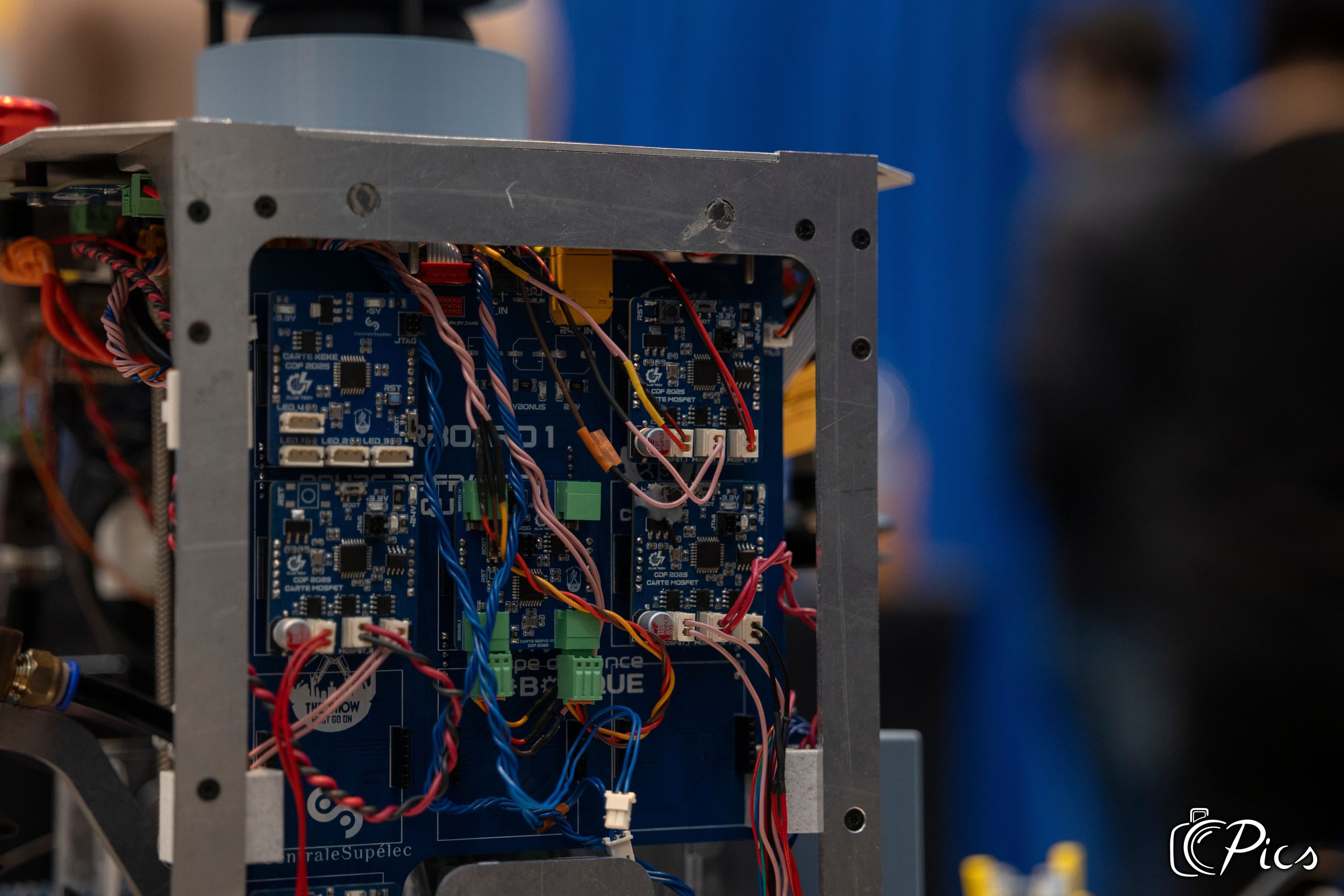

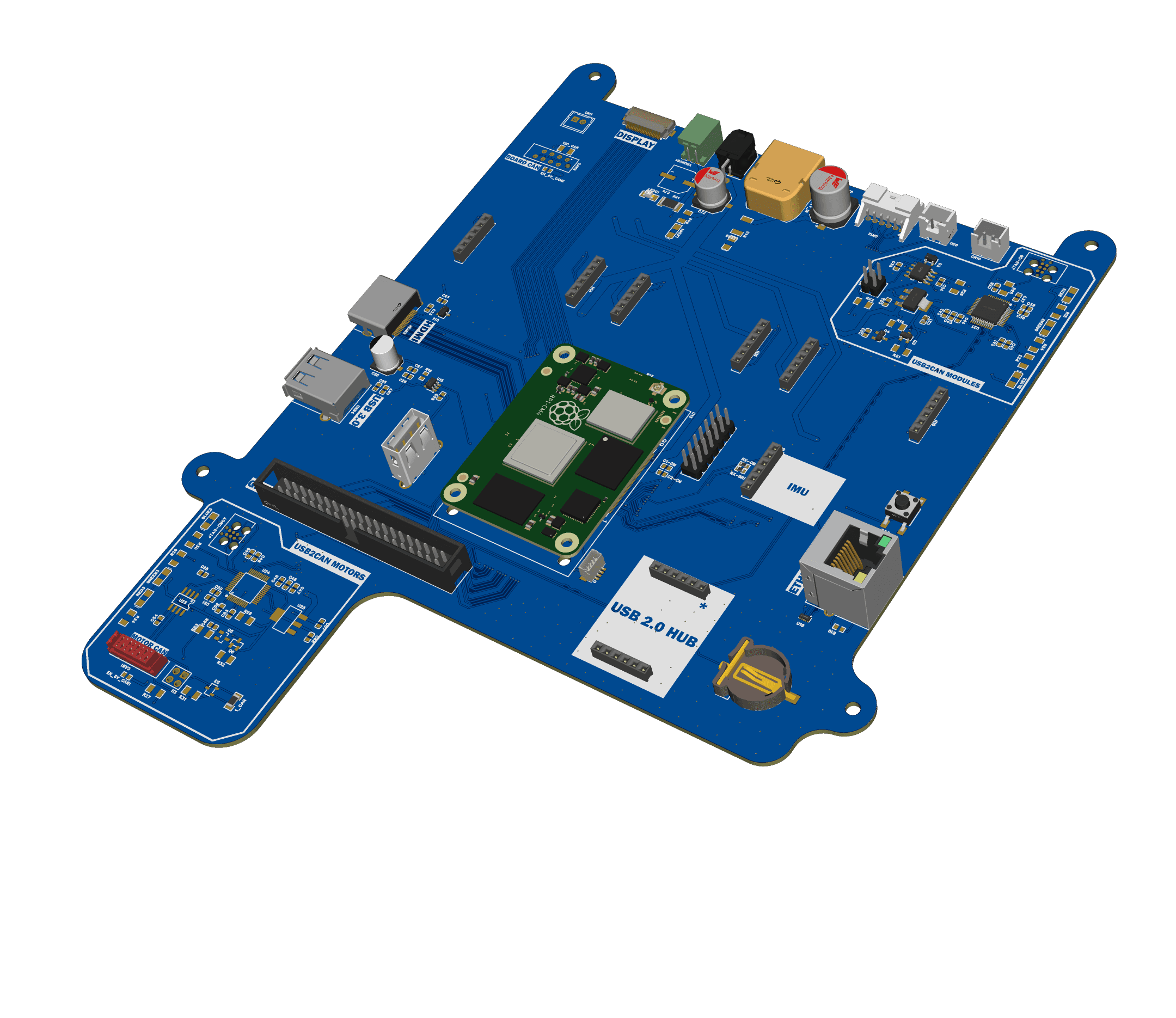

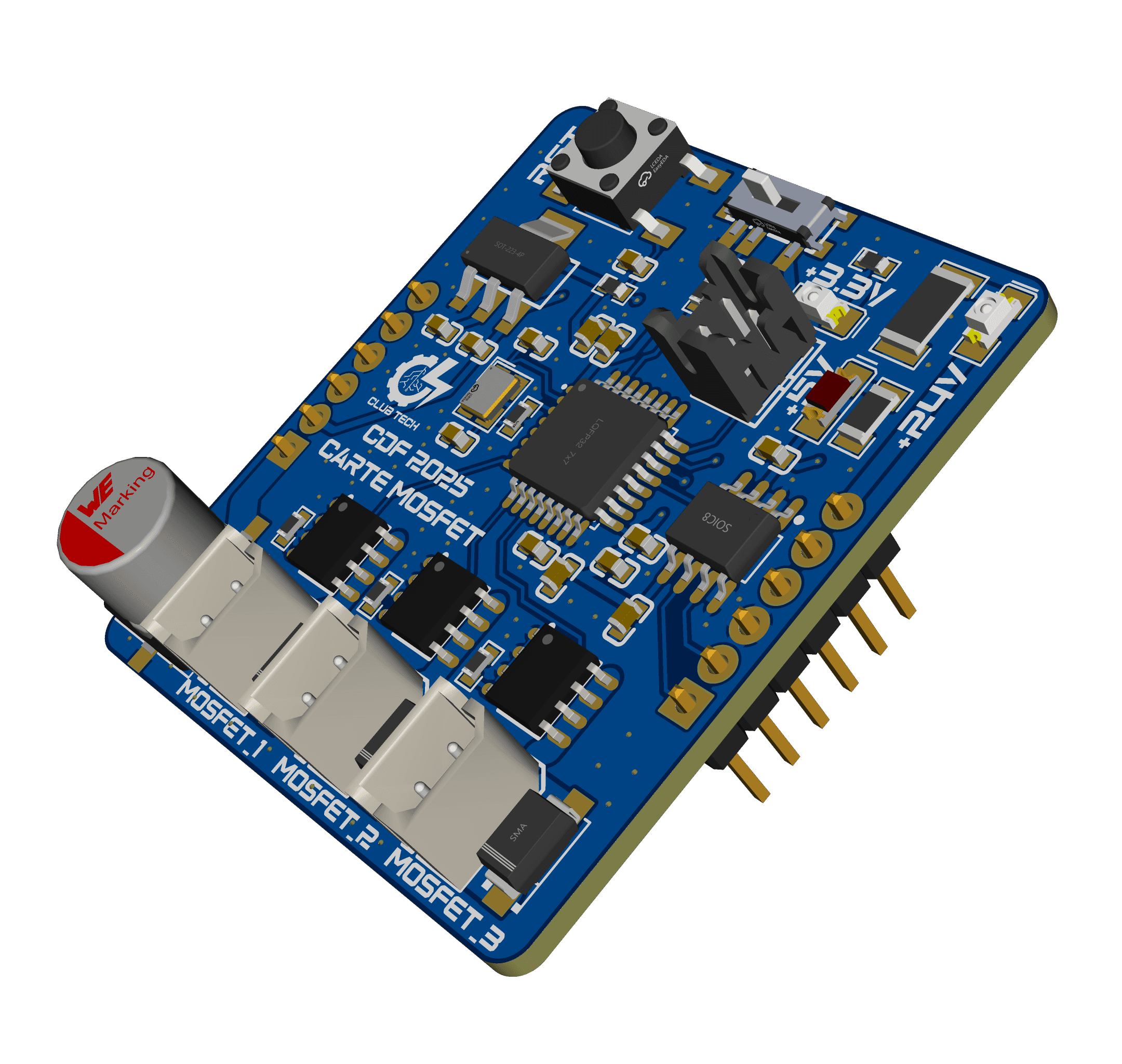

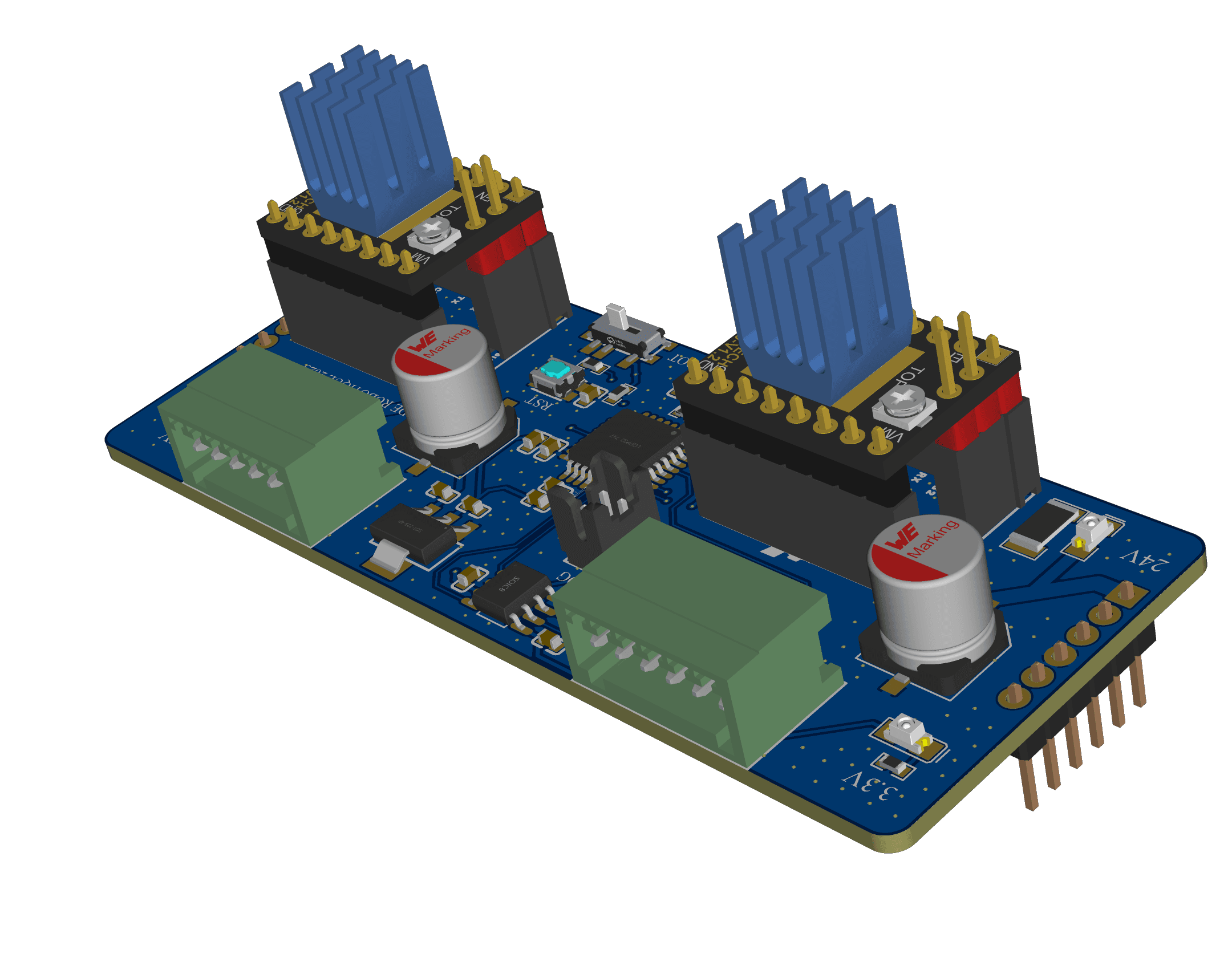

In advanced robotics, the most brilliant software can be crippled by the physical reality of its electronic hardware. With tight deadlines and the constant need for last-minute changes, the monolithic electronic architecture easily becomes a complex mess that's difficult to debug, impossible to scale, and a significant barrier to rapid innovation.As VP of Electronics at ClubTech in CentraleSupélec, I led the initiative to replace this complexity with a clean and standardized ecosystem. The philosophy behind our new system is simple: create a standardized platform that allows any component to connect and communicate seamlessly. We achieved this by designing a common backplane that provides a universal interface for all our custom modules. This interface delivers shared power ( and ), a common ground (), and a robust communication network using the CAN bus protocol ( and ). The choice of CAN was deliberate; it is an industry standard renowned for its reliability in electrically noisy environments, a common characteristic of robots with powerful motors. Each functional component, from a motor driver to a sensor array, is built as a self-contained module. Every module houses its own STM32 microcontroller, allowing it to manage its own operations and communicate intelligently on the network. To ensure physical compatibility, we standardized on single-slot and double-slot form factors, enabling us to build modules of varying complexity that all fit perfectly within the system.

The Anatomy of the Ecosystem

The Command Center: The Raspberry Pi Main Board

The Expansion Hub: The 10-Slot Backplane

A Principle of Self-Contained Units

MOSFET Power Module

Stepper Motor Driver Module

A Transformative Impact

- Radical Flexibility: We can now reconfigure a robot's entire hardware suite in minutes, not days. Swapping a sensor module for a new motor controller is as simple as unplugging one card and plugging in another.

- Effortless Scalability: The system grows with our needs. We can start with a minimal setup on the Controller Board and expand methodically by adding Expansion Hubs, ensuring the architecture never limits the scope of our ambition.

- Enhanced Reliability: By eliminating the "rat's nest" of wires and standardizing connections, we have drastically reduced the most common sources of electronic failure. Debugging is now a logical process of isolating a specific module rather than tracing a single wire through a complex loom.

- Accelerated Innovation: Our teams can now develop and test new hardware modules in parallel. A new sensor can be perfected on a test bench and, once validated, instantly integrated into the main robot, knowing it will work seamlessly.